Torch and Grit (TaG), a new test method for electric vehicle battery case material testing (VE), was introduced today by UL Solutions, a pioneer in applied safety research worldwide.

Electric vehicle safety depends on battery boxes and the materials they are composed of. The TaG test method consists of small-scale tests that forecast how materials will function when heated.

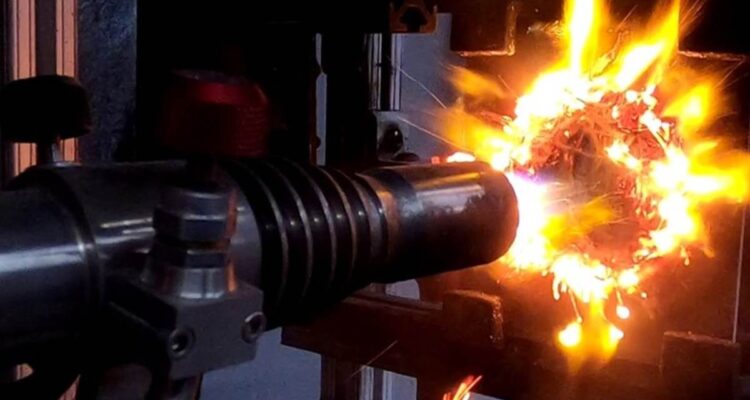

The design of battery enclosures and the materials used to construct them are crucial to the security of electric vehicles. Small-scale testing is part of the Torch and Grit (TaG) test method from UL Solutions, which aids in predicting how well a material will perform in a thermal runaway event.

The design of battery enclosures and the materials used to construct them are crucial to the security of electric vehicles. Small-scale testing is part of the Torch and Grit (TaG) test method from UL Solutions, which aids in predicting how well a material will perform in a thermal runaway event.

Typically, an electric vehicle’s base is made up entirely of batteries. These batteries’ housing materials must be able to endure the strain of overheating. The TaG method evaluates battery enclosure materials by simulating high temperatures and mechanical impacts in battery overheating circumstances.

Original equipment manufacturers (OEMs) are gradually substituting plastics and composites for metal in battery case construction as the car industry works to lighten the weight of many components. Before creating a pricey prototype, OEMs should select a suitable casing material to reduce costs and prevent any safety risks. TaG can decrease the quantity of materials needed for extensive prototyping and validation testing, which can be expensive and time-consuming for OEMs, by analysing materials.

Source: Prnewswire

No Comments