Source prnewswire

End-of-Life Li-ion Battery Sustainability: Its Crucial Role Over the Coming Years

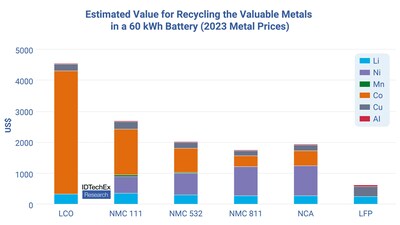

The use of lithium-ion (Li-ion) batteries has become ubiquitous throughout our daily lives, and the demand for Li-ion batteries has continued to grow over the last decade, particularly in consumer electronics, portable devices, electric vehicles (EVs), and stationary energy storage systems.. The EV market has been responsible for most of this growth and is now responsible for the majority of the global Li-ion battery market, with IDTechEx forecasting that by 2034, the market for EV batteries will surpass US$380 billion in sales.. As the demand for Li-ion batteries continues to grow, so does the need to manage their sustainability throughout all the stages of their lifecycle, including raw material extraction and processing, the use of batteries or their reuse, and, most importantly, at the end of their life cycle.. There are a number of factors that have also been driving forces behind the development of alternative energy storage technologies, in particular, in order to reduce the possibility of supply bottlenecks to materials such as lithium, cobalt, and nickel, as well as reduce their price. A Na-ion battery, for example, is capable of providing relatively similar performance characteristics to Li-ion batteries without having to use lithium or cobalt in their construction. There is also the possibility of using cheaper and more readily available materials, such as zinc, iron, or organic compounds, in order to build redox flow batteries, although the majority of deployments are based on vanadium electrolytes as the electrolyte materials.. However, despite technologies such as these having the potential to diversify material demand to more widely available and less environmentally problematic materials, Li-ion demand is forecast to continue growing at a rapid rate over the next few years.. Therefore, it is essential that Li-ion material supply and EOL management continue to be a priority in the future. You can find out more about IDTechEx's latest research on Na-ion, RFBs, and alternative storage technologies by visiting their website at www.IDTechEx.com.INTEGTECH EXPO.Visit http://www.energynews.comVisit http://www.energynews.comIn the ever-increasing demand for lithium-ion batteries, there is an increased need to ensure their sustainability throughout their entire lifecycle, such as the extraction and processing of raw materials, the use or reuse of the batteries, as well as at the end of their useful lives (EOL).. The development of alternative energy storage technologies has also been influenced by some of these factors, especially with regard to reducing the possibility of supply bottlenecks for materials such as lithium, cobalt, and nickel, all of which have been driving factors behind the development of alternative technologies for energy storage. The Na-ion battery, for example, can offer essentially the same performance characteristics as the Li-ion battery without the use of lithium or cobalt. Alternatively, redox flow batteries may make use of materials that are cheaper and more widely available, including zinc, iron, or organic compounds, although the majority of these batteries are based on vanadium electrolytes for a variety of reasons. Despite the fact that technologies such as these can diversify the material demand to more widely available and potentially less environmentally problematic materials, Li-ion demand is still forecast to keep growing at an accelerated rate over the next few years. Due to this fact, Li-ion material supply and EOL management will continue to be important. Click here to learn more about IDTechEx's latest research on Na-ion, RFBs, and alternative storage technologies, or visit their website at www.idtechex.com.IndTechEx (IDTechEx).Please visit http://www.com/EnergyPlease visit http://www.com/EnergyEnd-of-life lithium ion batteriesThere are several options that can be considered once a Li-ion battery has reached the end of its first life cycle. Among these are disposal, recycling or repurposing of materials for use in a second life. It is possible for Li-ion batteries to leak flammable and hazardous electrolytes into the environment, which can waste the remaining value or materials contained within the battery if the batteries are disposed of in the wrong way.. As one of the most common methods for repurposing (or remanufacturing) batteries for second-life applications, Li-ion batteries from electric vehicles are often reused in stationary energy storage systems. By using the battery in another less demanding application, it is hoped that we will maximize the value of the battery as well. In the process of recycling Li-ion batteries, we try to recover valuable materials, either from the constituents of the cell itself or from other components of the battery pack.. Battery manufacturers will find recycling to be an important tool to mitigate against potential future raw material supply constraints, fluctuating raw material prices, and to domesticate the supply of raw materials in the future Battery manufacturers will find recycling to be an important tool to mitigate against potential future raw material supply constraints, fluctuating raw material prices, and to domesticate the supply of raw materials in the futureRecycling of lithium-ion batteriesRecycling Li-ion batteries usually involves the recycling of materials such as lithium, cobalt, nickel, manganese, copper, and aluminum, which are all extracted from the batteries. It is typically a combination of mechanical, hydrometallurgical, and pyrometallurgical processing steps that are employed in reprocessing Li-ion batteries. Prior to the hydrometallurgical process, mechanical processing is employed. In order for a recycler to obtain the individual Li-ion cells from a battery pack, the pack would have to be disassembled once it has been received. As a result, they can be mechanically crushed, resulting in the formation of a powder known as black mass. As a result of hydrometallurgical processing, valuable metals in the black mass are selectively extracted by chemical reagents, which are then used to produce battery-grade metal salts (e.g., nickel, cobalt, zinc, etc)..As an example, lithium carbonate, cobalt sulfate, etc.). It is then possible to process these further in order to manufacture precursors for the production of the cathode active material for new batteries. There is no doubt that this is considerably more economical than manufacturing new cathodes from virgin materials, and several life cycle analyses published in the literature suggest that, in most cases, it causes less environmental impact as well.. The pyrometallurgical process can typically be carried out in a shaft furnace and is a high-energy process that produces both a mixed metal alloy as well as a slag stream consisting of lithium, manganese, and aluminum in varying amounts.. In order to recover all valuable metals from these intermediaries, further hydrometallurgical processing would have to be performed In order to recover all valuable metals from these intermediaries, further hydrometallurgical processing would have to be performedA recent report by IDTechEx predicts that hydrometallurgy will be the preferred technology for most recyclers, primarily due to its higher efficiency and lower energy requirements when compared to pyrometallurgy (see figure below).. As hydrometallurgical recycling requires disassembly of the pack and mechanical pre-treatment, recyclers looking to scale their recycling capacities for a full Li-ion recycling process would need to scale both their mechanical and hydrometallurgical capacities to meet the demand. It is clear from IDTechEx's 'Li-ion Battery Recycling Market 2023–2043' report that some players are opting for the 'Spoke and Hub' model, in which spokes are facilities that are exclusively focused on disassembly and mechanical processing, and hubs take the black produced by spoke facilities and use this mass to produce battery grade salts. It is clear from IDTechEx's 'Li-ion Battery Recycling Market 2023–2043' report that some players are opting for the 'Spoke and Hub' model, in which spokes are facilities that are exclusively focused on disassembly and mechanical processing, and hubs take the black produced by spoke facilities and use this mass to produce battery grade salts.There will also be new regulations in key regions such as the EU, India, and China in the near future that will drive the recycling of Li-ion batteries. In the EU Battery Regulation, there are targets for the collection rates of light means of transport (LMTs) and portable batteries, as well as specific material recovery efficiency targets for all Li-ion batteries, as well as minimum recycled contents targets in new EV and industrial batteries.. It has been announced that India will introduce 'Battery Waste Management Rules (BWM) 2022', which will cover EV batteries, portable batteries and industrial batteries with similar targets. Below is a summary of the EU Battery Regulation's targets Below is a summary of the EU Battery Regulation's targetsBatteries that have been reusedA battery may eventually reach the end of its first life span and no longer be able to meet the demands of an electric vehicle when it has reached the end of its first life span. A battery is typically considered to be out of service when it falls below a certain threshold for failure at the end of its useful life. According to the industry consensus, particularly for EV batteries, this occurs when the maximum battery capacity drops to 70-80% of the rated value of the battery at the end of the life of the battery. Even so, such a battery could still be utilized in a less demanding stationary energy storage application, and the cost of such a battery would be significantly less than that of a new Lithium-ion stationary energy storage system. It is vital, however, to test the retired battery to ensure that it is still fit for reuse, as well as deciding whether or not it is worthwhile to disassemble it at the cell level. State-of-Health tests and internal impedance tests are two of the most common tests used to assess the suitability of batteries for use in second-life applications. A battery with a State-of-Health of 70-80% can still be used for second life applications as long as it has a 70-80% State-of-Health A battery with a State-of-Health of 70-80% can still be used for second life applications as long as it has a 70-80% State-of-HealthIt is difficult to automate this process due to the fact that battery pack designs differ among original equipment manufacturers (OEMs). To disassemble EV battery packs, manual labor will be required, and the workforce that will do this will need to be reasonably skilled in order to disassemble packs of different designs safely.. As a result, disassembling to the cell-level takes longer, which increases the cost of manual labor as well. As a result of these reasons, the majority of second-life battery startups, scattered across Europe and North America, are currently integrating EV batteries at pack-level for use in the second-life battery sector. Several packs can be connected in parallel to form a stationary storage system that is large enough to store kWh or MWh. Research by IDTechEx's report 'Second-life Electric Vehicle Batteries 2023–2033' has suggested that currently, a large portion of second-life batteries are likely to remain in China, where they are used as backup power for telecom (4G, 5G) towers in order to enhance their performance. Research by IDTechEx's report 'Second-life Electric Vehicle Batteries 2023–2033' has suggested that currently, a large portion of second-life batteries are likely to remain in China, where they are used as backup power for telecom (4G, 5G) towers in order to enhance their performance.In spite of the fact that repurposing is cost-effective at pack-level, the performance of the pack will be limited by the weakest-performing cell in the pack. As a result, these repurposers will be leaning more on battery analytics tools and software to closely monitor the performance of these batteries and may have agreements in place with their customers that guarantee faulty batteries will be replaced as soon as possible. Considering that there will be no modifications made to the arrangement of the cells, repurposers would need to make sure that procured batteries are provided to them by an automotive OEM that guarantees a certain level of performance. As a minimum, this could be the State-of-Health (SOH) or the internal impedance of the system. Managing this supply of high-quality batteries requires partnerships between both automotive OEMs and repurposers in order to ensure that these batteries are available at all times while still managing the supply of batteries that do not meet these minimum specifications. Managing this supply of high-quality batteries requires partnerships between both automotive OEMs and repurposers in order to ensure that these batteries are available at all times while still managing the supply of batteries that do not meet these minimum specifications.Is it possible to recycle or repurpose batteries for use in second-life applications?In many ways, repurposing electric vehicle batteries for second-life applications is arguably a more technically challenging operation that is more labor intensive and with less predictable economics than repurposing EV batteries for new applications. Even though pack-level integration reduces remanufacturing costs, it relies more on repurposing companies using the best-performing batteries they are provided with and monitoring the performance of these batteries closely over the course of their second life.. In addition to this, repurposing does not replace recycling, but simply delays it and maximizes the value of the battery by repurposing In addition to this, repurposing does not replace recycling, but simply delays it and maximizes the value of the battery by repurposingAs well as battery manufacturers who are looking to domesticate the supply of material and protect themselves against shortages of virgin materials and fluctuating prices of virgin materials, policies will drive Li-ion battery recycling in some key regions. It is very important to consider which chemistries are more suitable for recycling or repurposing. From a material value perspective, LCO, NMC, and NCA chemistries represent a much stronger economic value proposition for recycling than LFP chemistries.

No Comments