Polyplastics Co., Ltd., a world leader in engineering thermoplastics, has created a novel EAC analysis method that can foresee the formation of voids in DURACON (R) POM injection moulded goods. In order to save time, money, and resources, this new EAC tool can forecast the risk of liquid forms before the mould is created.

You may view the accompanying photograph at: https://kyodonewsprwire.jp/prwfile/release/M100475/202211220145/ prw PI1fl 5xTHRjBB.png.

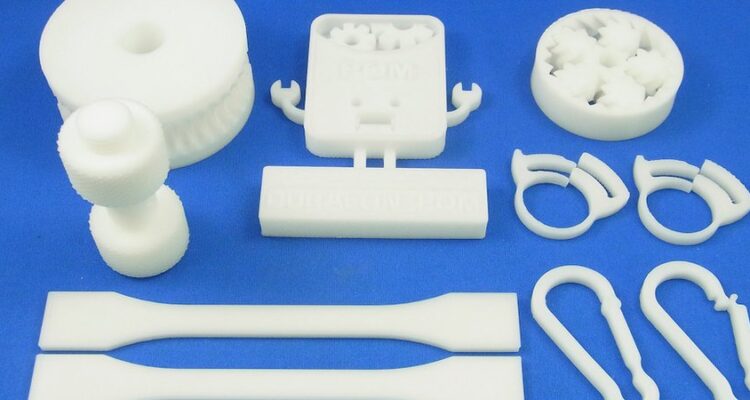

Vacuum prediction technology used by Polyplastics during the solidification of DURACON(R) POM resin accounts for changes in factors such as temperature and pressure. Visualizing the amount and location of voids, as well as the moulding conditions and effects of changes in gate position, is a key feature of this technique.

Hollow pockets, known as voids, are a common sort of moulding fault that manifest themselves in the middle of thick injection moulded items. Volume shrinkage, a byproduct of flow analysis, is one such parameter that has traditionally been used to anticipate voids, but its accuracy has been questionable because the phenomena itself cannot be replicated.

With the help of mould shrinkage, elastic modulus, and pressure distribution during the resin solidification process, the novel vacuum prediction technology can accurately forecast the creation of voids within moulded goods in response to stress. The technology has the potential to expedite the development cycle, lower the cost of product development, and reduce energy usage in simulations because of its ability to anticipate vacuums with high precision before mould building.

Polyplastics has developed new vapour-pressure prediction technology for POM injection-molded products, and is making it available as part of its standard technical assistance.

Source: Prnewswire

No Comments